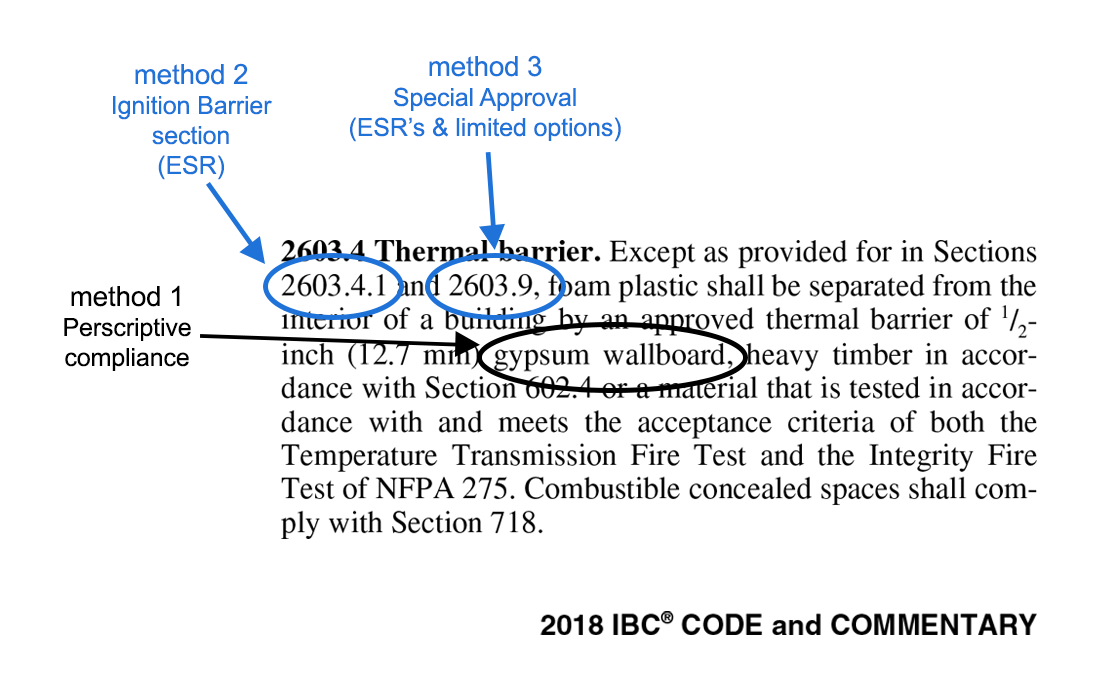

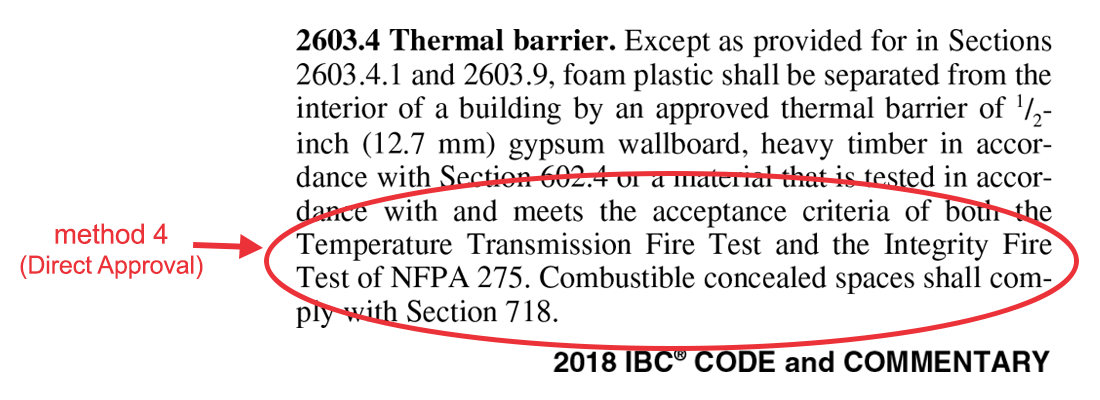

Although the IBC defines three methods of permittable thermal barriers, the specific section of the code allows four different methods. These exist primarily due to the unavailability of complete solutions in some cases and are allowed as deviations until technology catches up with the need for improved fire safety.

There are four specific methods in which plastic (and spray polyurethane foam - SPF) can comply with the thermal barrier code. The figure to the right illustrates three of the four methods:

-prescriptive (grandfathered) method, in black, and

-two exceptions (deviations) in blue. These exceptions are permitted for niche approaches to meet the code without direct compliance to 2603.4