SPF Thermal Barrier Solutions of the Past – “Add-on” Products Over Plastics

Spray foam insulaton (SPF) has historically met code by being applied behind gypsum or covered with approved, add-on thermal barriers – items like cellulosic and cementitious materials. SPF could also comply with code through “exception” methods using the lower-level ignition barrier approval (method two) or special approval testing (method three).

When choosing one of these methods, the questions are…

1. Which test(s) should be used?

2. Which combination of coatings or cellulose or cementitious materials should be used?

3. Over which foams?

4. At which thickness?

5. In which densities?

….a daunting task indeed.

Addressing all combinations of SPF/coating/cellulose/cementitious solutions and the appropriate paperwork required by building officials is a separate topic in itself, requiring much further research and explanation. However, understanding the add-on solutions is crucial and does need to be taught, if for no other reason than each skilled trade bears responsibility for the safety of the construction process and the end-result.

One overriding thought is that manufacturers who supply plastics for the building envelope often claim their products are “fire-rated,” and although overly vague and misleading, they are partially correct. All plastics require a minimal level of fire rating to even be allowed for use in buildings. The problem is the robustness of the test procedures referenced.

Figure six shows a range of fire tests commonly referenced. A company could claim a “fire rating” from a simple Bunson burner test lasting only seconds to full wall assemblies and ceilings that have achieved multi-hour ratings. Tests lasting mere seconds or claiming “self-extinguishing” with low-level heat or flame impingement provide less than acceptable protection for life safety.

Figure 6

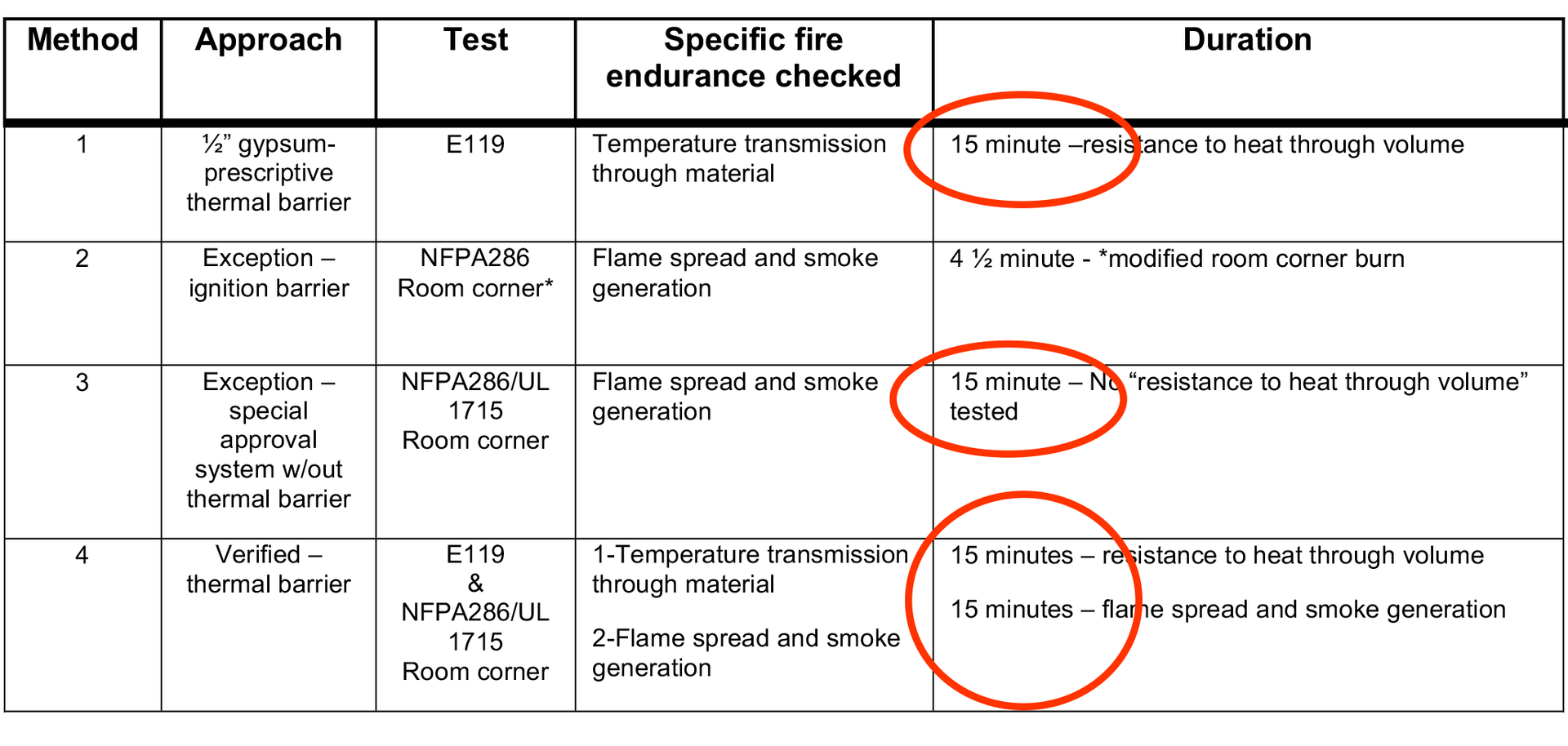

Prescriptive method one (gypsum) follows historical performance results and fire ratings are 15 minutes based on ASTM E119 “temperature transmission testing.” This is also sometimes called the compartmentalization of fire test. It tracks and defines the level of time it takes for extreme heat to pass through a wall or ceiling to create a fire-risk situation in adjacent rooms to the space that has been compromised by fire.

Exception method three (special approval) defines a 15-minute period where flame spread and smoke generation from a known fire source in an 8’ x 12’ room cannot exceed certain critical safety levels of flame and smoke. The flame and smoke growth limits over the 15-minute duration estimate a safe amount of time to evacuate the space. Method three almost always defines systems’ capabilities that work in conjunction to achieve a lower level but “code-allowed” solution to life safety, as it does not show compliance to temperature transmission risk in a structure. Although both tests have 15-minute durations, they certify two very different life-safety criteria that are not interchangeable.

Direct compliance, method four (NFPA 275 – also known as equivalent thermal barriers), is a test protocol that requires both tests – the temperature transmission test and the flame spread smoke generation test, both over a 15-minute period. Method four establishes a combination of both the prescriptive solution and the special approval solution and defines an equivalent replaceable thermal barrier to the gypsum prescriptive method.

It is a life-safety and liability issue; therefore, it is imperative for the builder, architect or general contractor to understand the various fire-rating methods and what they mean in order to protect themselves. Alternatively, find a trusted compliance partner, a fire consultant or a fire inspector.

Firestable FS 2.0 provides NFPA 275 compliance WITHOUT topcoats.

Call us today and we’ll show you double digit margin improvements.

Join the revolution: